As the world continues to move toward an ever-increasing reliance on electronics for a variety of uses, the question then turns to the protection of these electronic devices. Interference from radio frequencies and/or electromagnetic energy can be damaging to electronics and render them inoperable. In answer to this critical issue, there has been a great deal of research conducted on shielding and ways to eliminate radio frequency interference (RFI) and electromagnetic interference (EMI).

Methods of Protecting Electronics

There are three primary methods of preventing interference from radio frequencies and electromagnetic energy. The first involves a reduction of cables and wires so that no excess is used. A second method requires the installation of additional parts, such as inductors, circuit breakers or capacitors, in an effort to provide a filter system. Providing some form of enclosure for the electronic device is the final method of protecting these valuable parts. For many of today’s applications, enclosures provide better protection at a more value-conscious price point.

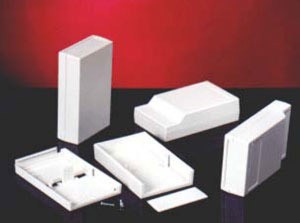

Plastic Enclosures Offer Superior Protection

Unlike enclosures made of other materials, such as metal or aluminum, plastic enclosures provide a material that is easy to work with in terms of RFI/EMI shielding. In most cases, plastic enclosures that are designed to offer such protection are sprayed with a lacquer with an acrylic base that is combined with copper or nickel. This coating prevents the electronic device within the enclosure from being damaged by radiation.

Importance of Using Plastic Enclosures with RFI/EMI Shielding

Frequency disturbances that one device can emit could damage another electronic device. Using plastic enclosures with RFI/EMI shielding provides a simple and effective method of ensuring that these frequency disturbances are not an issue. Because RFI and EMI can cause significant interference in devices — such as the suppression of the signals that a device generates internally, internally-generated emissions that can interfere with normal equipment operations or ambient external interference with other equipment operations — providing a method of shielding is imperative for the successful operation of many of today’s crucial industries.

Industries Helped by RFI/EMI Shielding

One of the most important industries in the world today — the telecomm industry — relies heavily on preventing the effects of RFI and EMI. A signal’s reception can be hampered other signals that are too similar in frequency. Using RFI/EMI shielding can prevent interference from those frequencies that are not correct. Within the medical industry, the Food and Drug Administration (FDA) has set strict standards that medical providers must comply with. Medical equipment must not be affected by those electronic devices that are found throughout the facility, such as cell phones, tablets and other electronic devices. RFI/EMI shielding ensures compliance with these regulations. Within the board room, protecting audio/visual equipment from interference from nearby electronic devices with the use of RFI/EMI shielding increases productivity while protecting valuable equipment.

SIMCO specializes in offering enclosures to meet a variety of needs, including plastic enclosures with RFI/EMI shielding. The coating they use, SprayLac, is the leader in the industry and offers superior results for SIMCO‘s customers. Contact them at 800.780.9090 for more information.