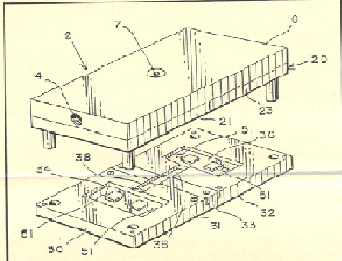

Industry insiders marvel at SIMCO’s injection molding technique. With several patent applications filed, this injection molding technique is being used to save time, reduce costs, and offer more options and accessories for customizing SIMCO electronics enclosures. This technique overcomes the disadvantages of the previously used pneumatic and mechanical techniques.

Industry insiders marvel at SIMCO’s injection molding technique. With several patent applications filed, this injection molding technique is being used to save time, reduce costs, and offer more options and accessories for customizing SIMCO electronics enclosures. This technique overcomes the disadvantages of the previously used pneumatic and mechanical techniques.

Customers have been requiring ever increasing enclosure customization. Changes are being made to various parts, especially to the front and rear panels that frequently need modified openings for different switches and controls. Previously, customizing enclosures in this fashion was cost prohibitive due to the increased lead times and the cost of molding custom parts. SIMCO set out to develop a technique that allowed it to fulfill customer demand for customized enclosures at a cost that is economically viable.

Previously, SIMCO used replacement cavities and core portions to reduce the cost of customization. SIMCO was using multi-family molds that added variety to what their existing molds could produce. Weaker materials were also sometimes used as a means to reduce the tooling costs. The development of the injection molding technique was SIMCO’s answer to the need for a significant improvement to those methods.

Injection molding advantages

When using injection molding, the means for ejecting the molded parts form the mold cavity must be moved frequently. Thus, an efficient means for removing these molded parts is needed. Until SIMCO’s injection molding technique, relocating the means for ejection complicated the customization process, defeating the attempts to reduce costs due to the risk of creating serious quality issues and operating deficiencies.

With SIMCO’s technique, these deficiencies have been overcome. The use of an ejection technique located completely within the molding plate eliminates changes to the mold exterior that were necessary previously. Now, it is much easier to accommodate customer requests for customized locations and dimensions.

Often, enclosure designs are not accounted for during the initial product design stage. The unexpected need for redesign that results from this mistake can be costly. Custom tooling is expensive. Beyond economic costs, however, redesigning enclosures after work has commenced also costs companies time and flexibility.

Custom tooling is needed for the production of custom enclosures, and this takes time. Lead times can be as long as six months. The process is also very expensive. The engineering fees alone for designing the toolings can be enormous. Then, there is the cost of producing the mold. All of these costs must then be rolled back into the price of the product; otherwise, they will take a serious toll on the profit margin.

The injection molded enclosures offered by SIMCO allow for a variety of ways to customize enclosures with different options and accessories. These options give the resulting product a unique flair. Handles, tilt stands, upgraded materials, and custom colors are all now economically feasible. SIMCO offers an impressive selection with over a dozen standard models. SIMCO’s success is also based on their dedication to customer service and to delivering the best products at the most affordable prices.