Simcobox is an experienced company that started in 1982. The company has been manufacturing reliable enclosures for over 25 years. Due to the increase of the number of users, Simcobox also formed a sister company.

People know the company for selling its products at very low prices. Since Simcobox makes the shelters, the firm is able to respond to the needs of customers than other companies.

If you do not know how to select a cover, the team at Simcobox is ready to help you. They will assist you to choose the best cover for your project. They will also guide you on the best way to change the enclosure to suit your needs.

Simcobox works with a special chart. You can use this chart to choose the size of case that is closest to your desired needs. In case you want to make any changes later, the chart allows for that as well. In addition, you can get free user drawings and free samples to help you even further.

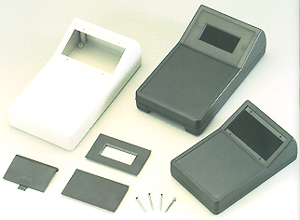

When it comes to plastic covers, the company has a variety of styles for you to choose. Some of the cases require a set of accessories in order to work properly. Below are some of the plastic accessories that Simcobox offers to clients.

Plastic Belt Clips

These are some of the main accessories you can find at Simcobox. The clips are useful because they allow the user of the equipment to fix it on the belt. This prevents the enclosure from falling and being damaged. In addition, the accessory enables you to use the equipment while your hands are free.

Simcobox’s plastic belt clip comes in a style that is easy to use. You do not need complicated parts or many changes to start using the clip. To start using the clip, use the plastite® fasteners used for box assembly.

Screws

The screws are other crucial plastic accessories offered by Simcobox. Simcobox gives the important screws for fixing all the plastic cages. In case you need more screws, the company offers them as well.

The plastite screws are especially popular for abs plastics. These accessories have specially shaped heads. This means that you do not need to use lock washers on them. Simcobox’s screws are also designed in such a way that it is very easy to fix the case.

Mounting Brackets

Mounting brackets are another addition to the plastic enclosure that you might consider. These accessories allow you to fix the Simcobox cage wherever you want. The company manufactures these accessories using aluminum.

They also apply a black power coat to finish. Another big benefit of the accessories is that they come with all the necessary hardware.

Rubber Feet

Rubber feet are essential for a plastic shelter because they prevent slipping, reduce noise, and protect the surface where you place the equipment.

You can get rubber feet in different styles including large, medium, and small.

Plastic Battery Doors

Of course, you will get a case that has a battery door if the equipment you buy uses chargeable batteries. Such covers have the door included in the order. However, you might need more doors in case the first one is damaged. So, if you need doors to replace the first one, make sure you include that in the order.

Tilt Stand and Handle Kits

Simcobox tilt stands are manufactured from strong and high quality type of steel. This, added to the special buttons, makes the accessory suitable for even the most difficult environments.

Front and Rear Panels

Simcobox is also popular for the manufacture of rear and front panels for cages. You can use these panels for different situations. As for the cage, ABS plastic is used to make these accessories.

PC Board Mounting Bosses

The Simcobox cover also comes with several mounting centers. The goodness brought by these centers is that you can use these accessories wherever you need them. This is because Simcobox also offers bonding agents, for example MEK. To hold the PC board tightly, the push-on fasteners are available as well.

Most Reliable Plastic Accessories

Ever since Simcobox first emerged, the plastic enclosure industry has never been the same again. Today, clients from all over the world use products from the company to serve many needs.

Products from Simcobox are very easy to use and of high quality. The company offers a wide range of accessories that include mounting brackets, rubber feet, screws, panels, and belt clips. Furthermore, you can use the products in different situations. To crown it all, the company sells the items at very good prices.

Are you looking for the best plastic accessories for your plastic shelters? Contact the technicians at Simcobox and make your order today. You will be guided be the team so that you can get an accessory that serves you well.