You want your electronic devices to last and ensure that they will be serving your employees for years to come. You made an investment in your electronics, and your employees, for that matter, so why not make one more small investment and protect your devices inside plastic electronics enclosusre?

You want your electronic devices to last and ensure that they will be serving your employees for years to come. You made an investment in your electronics, and your employees, for that matter, so why not make one more small investment and protect your devices inside plastic electronics enclosusre?

Why, you might ask, do you need enclosures? All around us, every day, there are things that can cause harm to our sensitive electronics, not the least of which are radio frequency (RF) waves that are emitted by other electronics and electromagnetic (EM) waves that can come from a number of sources, including solar ejecta. While they provide us with the dazzling Northern Lights, they can also provide interference with the proper operation of electronics. Ever noticed your satellite TV signal fuzzing out on a clear, windless day? Chances are good that it is the result of electromagnetic waves. Now, imagine what that can do to your portable electronics.

RF and EM waves can cause signals to be broken up, or even a loss of data while transmitting. The good news is that electronics enclosures can block these and keep your data safe. Whether pre-made or custom built, you can be assured your devices will run much more smoothly when they are properly shielded by these enclosures.

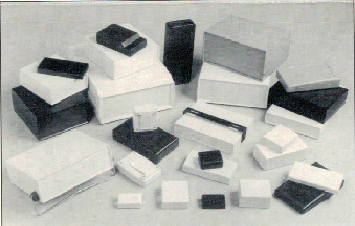

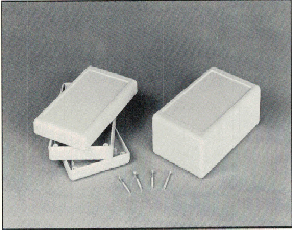

Enclosures are made from high-quality and long-lasting molded ABS plastic so they are not only functional, but also attractive. The enclosure can even be made from a colored plastic to help it blend into your office setting better. Rounded corners provide a level of comfort too, should you bump into one of the enclosures. The device inside the enclosure is also shielded from damage due to dampness in the air, dust particles, or industrial dirt as found in a warehouse or fabrication shop.

Dampness and electronics do not mix. The moisture can collect on the tiny metal components and corrode the metal, causing irreparable damage to intricate circuit boards. Dust might not seem like it would be harmful, since it is so soft, but it can actually get into devices and cause read/write errors or block up cooling fans. Electronics enclosures quickly become your electronic devices’ best friends, protecting them from the environment.

Speaking of the environment, when you are choosing a company to buy your enclosures from, look for one that complies with the various governmental regulations about proper chemical handling and environmental standards. In the United States, OSHA has requirements about clean air and the number of volatile organic compounds (VOCs) that can be released safely.

The European Union has passed some stringent regulations that govern how chemicals are handled and imported. This is covered by REACH, the Registration, Evaluation, Authorization and Restriction of Chemicals program that requires registration of certain chemicals above a set amount with the European Chemicals Agency in Helsinki, Finland. The EU also regulates six particularly dangerous chemicals, including lead, through the Restriction of Hazardous Substances, or RoHS, program.

Companies like SIMCO that have been in business a long time have built their business on customer service and being kind to the Earth. Select your electronics enclosures from a reputable and trusted manufacturer and you will not regret your choice.

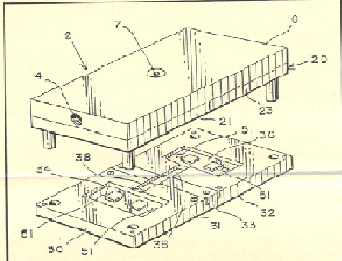

SIMCO Industries has introduced a product line called Enterprise, a molded plastic container designed for those larger places that need a secure protection to hold their manufactured electronic components. Electronic components need a protective environment that will shield them from wind, rain, dust, and air pollutants. Although many containers have been produced, they are often too flimsy or too small to hold the more complicated and delicate instrumentation required in today’s manufacturing environment.

SIMCO Industries has introduced a product line called Enterprise, a molded plastic container designed for those larger places that need a secure protection to hold their manufactured electronic components. Electronic components need a protective environment that will shield them from wind, rain, dust, and air pollutants. Although many containers have been produced, they are often too flimsy or too small to hold the more complicated and delicate instrumentation required in today’s manufacturing environment.

You want your electronic devices to last and ensure that they will be serving your employees for years to come. You made an investment in your electronics, and your employees, for that matter, so why not make one more small investment and

You want your electronic devices to last and ensure that they will be serving your employees for years to come. You made an investment in your electronics, and your employees, for that matter, so why not make one more small investment and