There are many kinds of enclosures available in the market but the most prominent are those made of plastic and metal. In this post, we will differentiate what are plastic enclosures and what are metal enclosures.

Plastic Enclosures vs Metal Enclosures: The Difference

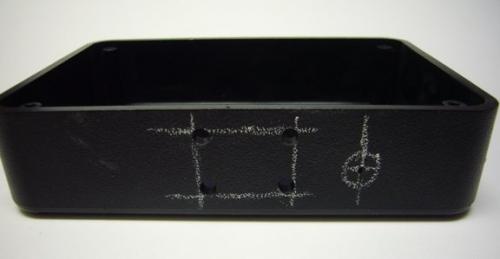

Source: SEPA

Metal enclosures have long been one of the most important parts in houses as well as office buildings. It is a purpose made cabinet for switches, knobs and for various electrical components that are wired in the house’s main supply. The only part of the equipment which is visible to the people in the building is the enclosure.

It is not only designed for easy use, but also for pleasing. It conceals look to the surrounding so that it does not reflect any mess. The matter of fact is that which type of part you want to install? And! What kind of material would it be made of? There are mainly two types of enclosures available in the market. One type is made of plastic which have several sub divisions and the other one is made of metal.

There are many advantages of installing metal enclosures. One big benefit of metal enclosures is that metal enclosures are a lot more resistant to weather. If you live in hard conditions where you experience a lot of rain or moisture then you must consider the material.

In wet conditions, metal enclosures are a good selection for you. This is because even with protected plastics, there is a lot of chance of the plastic swelling up. Plastic is not preferred because of deforming issues especially when that plastic is attached to metals. Rust is a big reason of loss and other huge drawbacks for the metal enclosures. But, if you use metal enclosures coated with aluminum, then you will not even have to deal with rust. Another plus point that you will have with a metal enclosure is that it blocks all sorts of interfaces.

If you reside on a hill top or near an area with higher levels of noise pollution than you must go for a heavy shielded metal enclosure. It blocks all sorts of interferences. If you reside on a hill top where antenna interferes is very high then you will need a metal enclosure. It will become a sort of an extra lifeline for your wiring systems. Moreover, you will have better grounding facilities if you opt for a metal enclosure. With this type of enclosure you will also have static protection. In case of radio switches, it is very effective. However, this form of enclosure has a few drawbacks. Mainly included drawbacks are: it is more expensive than its parts made of plastic. But the fact cannot be ignored that it lasts quite longer than plastic enclosures and is far more durable.

When dealing with plastic enclosures there are many advantages. Main considerable fact is the protection it brings along with it. The best advantage that you get from plastic enclosures is that they are very cost effective. You can get a plastic enclosure for a far lesser price than a metal one.

Furthermore, it is easy to install as well due to its lesser weight and easy handling. The metal enclosures are bulky and difficult to fix. Plastic also provides protection from UV radiations. This is particularly more useful in rough areas where the temperatures are high and hot. Due to these factors, plastic enclosures are used excessively for small junction circuits that usually handle in the premises of the house.

Cable holding is also a very positive thing because this material has greater elasticity. It increase protection for the wires inside the circuit.

Plastic enclosures are usually tough industrial protection and are far better option. This is because there are chances that it may even be submerged in chemicals or water than. This is because it does not react with the chemicals. It protects the inner wiring of your circuits very closely from any kind of contact with water or short circuiting. Though, this sort of enclosures also has drawbacks that can cause bad outcomes.

First of all, if you use an outdated plastic such as PVC then it can be harmful. It can come to contact with UV radiations and can cause high emissions. Such emissions into the environment can damage the ozone layer. Secondly, if you use low graded plastic then it can swell up at different temperatures. In moist environments, it can cause a lot of troubles for the circuiting as there will be increased chances of short circuits. Its life is also short which means at times plastic enclosures are termed as short lived.

In the end, it can be easily said that the choice of the right material of your enclosure depends upon the surroundings. If you live in in an unstable climate with high weather difference then metal enclosures suit you. However, in industrially bad environments with greater heat, plastic enclosures will be the best choice.