Plastic molding and more specifically plastic injection molding is becoming a more and more popular hobby for many enthusiasts. Plastic injection molding is the process of manufacturing plastic parts of all kinds and is actually the preferred way to do it. The process is used to produce parts like combs, bottle caps, containers, electronic housings and even automotive interiors as well as many other components.

Many people who like to produce their own things like plastic molding because it has numerous advantages such as the little effort needed to finish the parts after the molding process, minimal losses in terms of scrap, large selection of materials, repeatability and high tolerance precision.

The best polymers for plastic molding

When it comes to injection molding, the number of polymers which can be used is quite large. This includes some elastomers, some thermosets and all thermoplastics. There are literally thousands of materials enthusiasts can chose from.

Materials can also be mixed with various blends or alloys for an even larger selection and this is what some people do in order to ensure they have the material with the properties they need. Ideally, materials should be chosen based on the function and strength desired for the part that is going to be produced. However, each material’s individual parameters for molding should also be considered.

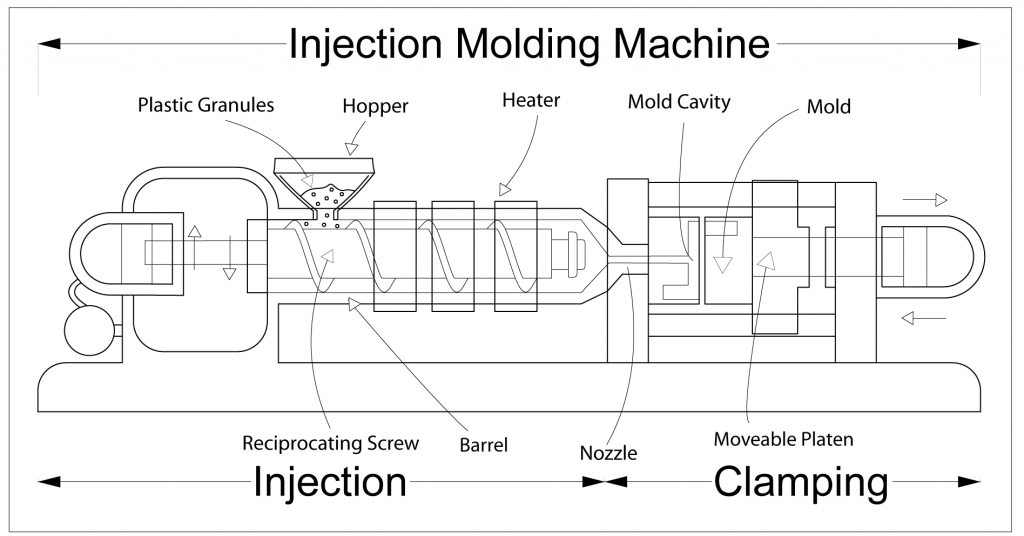

Injection molding equipment

Image Source: Wikipedia.org

If you are serious about plastic molding, you will need the right equipment.

Machine

The plastic molding machines are also referred to as presses and they consist of a heating unit, a screw-type or injection ram plunger and a material hopper. The machines work on a very simple principle. First, plastic is inserted in the form of grains, which are then heated and injected into a mold.

There are various machines people can choose from and they all have their tonnage. Tonnage refers to the clamping force of each machine. Some machines have a tonnage of 5 tons or less while others can reach 6,000 tons. The right tonnage is very important and it should be chosen based on the projected area of the part you’d like to create.

Mold

In order to be able to create your part, you will need a mold. Molds can be constructed from various materials including a beryllium-copper alloy, aluminum, pre-hardened steel and hardened steel. The choice mainly depends on the amount of parts that are going to be produced and their type.

Steel molds are usually expensive but can last a long time and therefore allow for a larger number of parts to be produced. One of the best materials for molds is aluminum. Aluminum molds are less expensive than steel ones and depending on the grade of the aluminum, can be used for the production of thousands of parts. They also offer faster cycles and a quicker turnaround due to the better heat dissipation that they offer.

Plastic injection molding is a great way to produce various useful parts affordably, especially when such parts cannot be bought elsewhere. The process is really simple once you understand it and the wide range of materials and molds can help anybody produce what they need.