Plastic enclosures are the most popular way to protect electronic devices from any harmful effects. Often electronics manufacturers choose aluminum and steel for their enclosures, but the recently introduced more durable types of plastic are about to change this

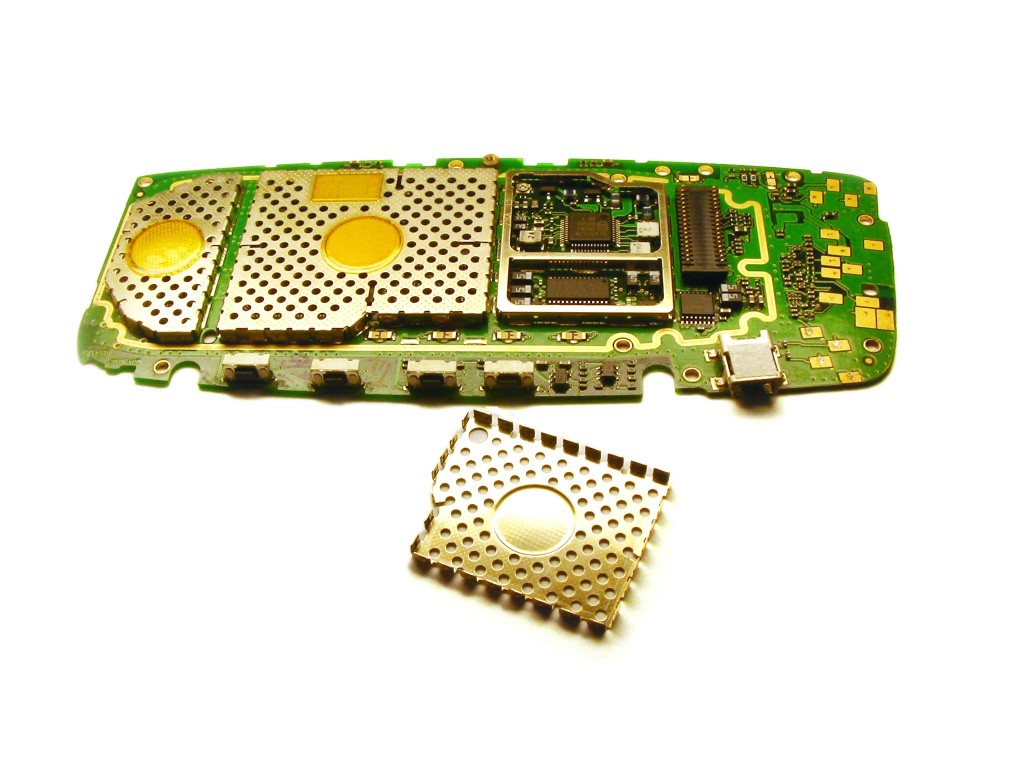

Image Source: Wikipedia.org

Image Source: Wikipedia.org

Although, choosing the best material for your electronic device’s enclosure requires understand the exact requirements of the particular project, for most of the items you can save a lot of money by using plastic. Furthermore, used in the right conditions, plastic enclosures tend to last longer than these created from other materials.

Most Important Plastic’s Features

The main difference between the plastic and other materials used to create electronics’ enclosures is that it doesn’t conduct electricity. This feature is especially important if there are concerns about electrical shortage or the device will be used near water.

Another feature where plastic comes superior is its weight. If you plan to outsource the assembly of electronic devices or for your particular project – enclosure’s weight plays vital role, definitely plastic is the best material for your needs.

Costs play important role for every electrical device project and plastic is reasonably cheaper than aluminum, steel and other metals used to create electronics’ devices enclosures.

Finally, metal enclosures require finishing, while plastic doesn’t. This alone eliminates one step from the production process without risking the durability of the plastic enclosure.

Polycarbonate vs. Phenolic Plastics

There are 2 main types of plastic used during the creation of plastic electronics enclosures – polycarbonate and phenolic. While both provide extensive durability, they are manufactured using different processes and understanding these could help you make the best choice for your project.

Polycarbonate is synthesized from wide range of different materials. Polycarbonate is one very strong, flexible across all temperatures and for that reason it has high impact rating.

Phenolic plastic is synthesized from coal. It’s turned into usable plastic, by heating the coal until it melts and pouring the resin into a mold. The phenolic plastic is very hard and extremely durable, with very high tolerance to arcing.

Plastic Certifications

The best way to choose safe plastic for your project is to make sure it comes with safety certification – the UL certificate is the most popular in the industry. To meet the certification requirements electronic plastic enclosures need to be create from material approved by the UL and also there are certain thickness requirements to conform with.

Assessing Your Needs for Plastic Enclosures

To choose the best materials for your electronics’ enclosures you need to assess your project requirements right. This is the best way to ensure that your device will work properly under the given conditions.

Although, plastic offers lots of options and flexibility, in some cases you just can’t use plastic enclosure for your electronic device. Choose the enclosure material carefully if you don’t want to reduce its durability.

Comments

One Coment

RSS