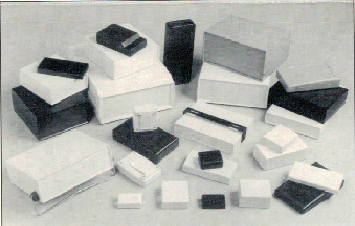

The CHALLENGER Series by SIMCO is a line of over a dozen new, plastic injection molded electronics enclosures. Many of these enclosures are completely new sizes that were designed according to the requirements of existing SIMCO customers. Others include completely new options that make the electronics enclosures more versatile for SIMCO’s customers.

The CHALLENGER Series by SIMCO is a line of over a dozen new, plastic injection molded electronics enclosures. Many of these enclosures are completely new sizes that were designed according to the requirements of existing SIMCO customers. Others include completely new options that make the electronics enclosures more versatile for SIMCO’s customers.

The CHALLENGER electronics enclosures materials

The CHALLENGER electronics enclosures are constructed from the same high impact ABS material as other SIMCO products. The material gives the enclosures their characteristic soft, velvety feel while still being scratch resistant. CHALLENGER Series enclosures are available in SIMCO’s three standard colors – Black, PC Bone Grey, and Dark Grey. Available options with the CHALLENGER enclosures include EMI/RFI shielding, UL 94V9 approved materials, and other options that add value.