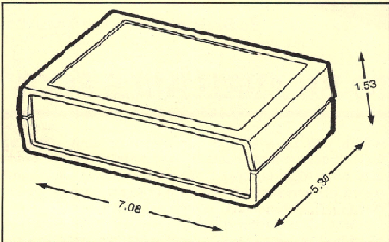

Enclosures are used in the industry to cover a wide range of devices. Most industrial places have these boxes. You can also use the cases to carry other items apart from those found in the industry. The boxes are very important because they protect tools from dust, water, and chemicals, among others. Some of the materials that makers use for enclosures include fiberglass, stainless steel, aluminum, and sheet metal. In the same way, enclosures come in different sizes. There are also those covers that are fixed while others are portable.

A further division of the portable covers gives both handheld and pocket size types. Handheld covers range between 6 and 11 inches in size. They are slightly bigger than pocket size covers, which measure about 3 inches.

You can use pocket sized covers to carry many types of equipment. Common uses of pocket size covers include infrared devices, radio frequency (RF) devices, personal security tools, medical gadgets, and measurement tools. You can also use these cages to carry small things such as jewelry, mobile phone, keys, and media players.

So, why would somebody use a cover as small as the pocket size one instead of the bigger ones? The main feature of these kinds of enclosures is that they keep the equipment in a fixed position. Therefore, pocket size enclosures have the following advantages:

Reasons You Need Pocket Size Enclosures

Pocket Size Enclosures Can Be Changed Easily

It usually easy to alter certain covers, especially those made from plastic. However, the job is even easier if you are dealing with a pocket size enclosure. As long as you have the right machine, working with a small device is easy. Modern VMC milling machines can produce customized products with very high degrees of accuracy.

When the customization is being done from a standard part, the part must first be secured on the machine. Then, the drawing of the desired part is loaded into the machine and the right tools as well. Then the operator starts the machine so that it can create the slots, holes, tapings, and so on. If you are to do such kind of change, you will find pocket size covers very easy to handle. Whatever material you are using, small covers will always be easier to machine, drill, chamfer, and so on.

The Ease of Movement of Devices is Increased

Movement of certain cages is very important, if you desire to use your device in different places. For example, people are nowadays walking around with medical tools, media players, and cameras. If there were no small sized cages, users may have to think twice before carrying such delicate devices. Makers are able to make pocket size cages that cover small devices for better use and security.

The main use of a pocket size case is to make a device easier to carry. Some devices do not have good handles and carrying them can be a problem. Pocket size cases solve this problem very easily.

The Cases Have Higher Resistance to Damage

Impact resistance is simply the ability of an object to resist breakage in the event of a sudden force against it. When a case falls, it suffers an impact. The larger the object is, the higher the effect of the impact will be, and vice versa. Most manufacturers create enclosures with the consideration of this resistance in mind. However, you can draw an extra advantage by going for pocket size cases, if your device is small enough.

They Use Less Material to Make

Even for the small devices, the maker has the option of using large cases. However, it is better to make pocket size covers and use less material. This is very important if you look at the cost of production. By using small sized covers, companies are able to save a lot of money and make more profits.

Outward Appearance

The look of any product is very important. If the good is not so attractive in its normal form, you can use a pocket size covers to hide the “flaws”. Some companies have also taken pocket size cases as a way of marketing. You can add certain features of your business, for example the logo or tag line, on top of an enclosure to market your business. This is an easy yet effective form of marketing. Whenever the user removes the enclosure in front of people, your business will have gained some mileage in terms of reach.

Final Take

There are many types of cases in the market. These covers vary in terms of size, material, weight, and design. Each of these covers has its own share of advantages and disadvantages. When you are choosing a pocket size enclosure, be sure that it can handle the size and weight of the device. You also need to know the level of modification needed to decide if the pocket size enclosure can handle it. This way, you will be able to experience the many advantages of pocket size enclosures.