The expander is able to solve the minor difficulty of designers and engineers of their handled devices being too large for the original Discover series, by providing height to an already functional product.

The expander is able to solve the minor difficulty of designers and engineers of their handled devices being too large for the original Discover series, by providing height to an already functional product.

Simco’s Discover series has become known for its innovative enclosures that are specifically designed to fit small-sized electronic devices. They offer impressive protection from the wind, water, and air pollutants and are available to fit the customer’s needs. However, with its new line in the Discover series, Simco delivers a product that fits the needs of customers with bulkier hand-held electronic devices.

Expander specifications

The Discover enclosures themselves are built at a height of 1.40”. The EXPANDER rings add an additional .5625”. This gives the entire enclosure a height of almost two inches. This large size is enough to fit almost any handheld device available on the market today.

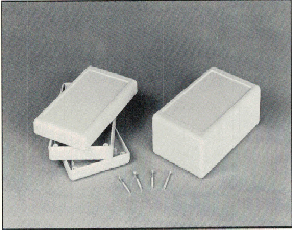

Simco’s expander for the Discover series can be added to any of the Discover enclosures with little installation. The Discover series has a panel and is screwed in with two screws. The EXPANDER ring is installed as simply as the rest of the enclosure. It fits snugly around each side of the enclosure and is held in place by four plastic screws and clear self-adhesive. The parts necessary for installation come included with the product.

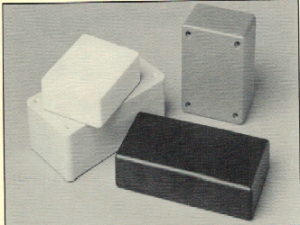

These rings come customized as well to allow either a unique appearance with contrasting colors or a simple matching color. They come in the same colors as the enclosures; sand, dark grey, PC bone grey, and black.

Additionally, the EXPANDER rings come with a customized design for both top and bottom. The 36SXRB comes with a sloped top, an XPANDER, and a plain bottom. The 36SXRDB comes with a sloped top, an XPANDER, and a deep bottom. The 36XR9VB comes with a sloped top, an XPANDER, and a 9V battery bottom. The 36TXRB comes with a plain top, an XPANDER, and a plain bottom. The 36TXRDB comes with a plain top, an XPANDER, and a deep bottom. The 36TXR9VB comes with a plain top, an XPANDER, and a 9V battery bottom.

The XPANDER itself also has a unique style. In addition to the multiple available colors, it comes lightly textured. It can also be molded with any of the high-impact materials that the enclosures are made of. Because most of these molds are scratch resistant, it will increase the durability of the XPANDER ring.

With the new XPANDER ring as an option, Simco’s Discovery series has become an ideal enclosure for almost any hand-held electronic device. This includes remote controls, portable equipment, and keypads, among other options. Its wide range of functional options and multiple designs also give it a customizable experience that will please any customer.

We hear it on the news every day – the economy seems to take one step back for every step forward. You made it through the toughest part of the recession and now you’re finally in the position to upgrade your employees’ computers, and you’re able to get your field team those handheld devices that you know will speed up receiving payments from customers as well as give your team a competitive advantage. You worked out the budget perfectly, but then you hear about

We hear it on the news every day – the economy seems to take one step back for every step forward. You made it through the toughest part of the recession and now you’re finally in the position to upgrade your employees’ computers, and you’re able to get your field team those handheld devices that you know will speed up receiving payments from customers as well as give your team a competitive advantage. You worked out the budget perfectly, but then you hear about

Providing protection for your computers and other devices is an important part of your overall network. One easy way to do this is to encase your devices in custom

Providing protection for your computers and other devices is an important part of your overall network. One easy way to do this is to encase your devices in custom