The number of people who are looking for medical items is increasing. At the same time, people are looking for cheaper items that are safe. In addition, people are now using cleaner items in order to follow needs of safety, easy make, and comfortable use.

Some of the machines you find in the hospital are movable while others are not. All of the machines in hospitals work in different ways. Therefore, the person making them should be careful which item he or she uses.

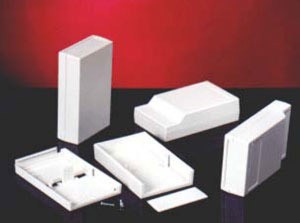

Source: Armstrongmold

Luckily, the newest items in the market are able to work even in very difficult areas. Plastics are the most popular items for making cages. This essay looks at the traits of plastics. It also shows the good of plastics bring when used for cages in hospital.

Medical Plastic Enclosure

Apart from plastic, other common items for cages are fiber glass and steel. The item you use will depend on the value it brings to you and the specific use of the cage.

When looking at plastic, consider the chemicals in it. Plastic cages are composed of units called polymers. A polymer is a mixture of smaller units called monomers.

Some of the plastics that you will find in hospitals include PP, PC, PA (Nylon), and PPS. Each of these items has pros and cons.

Source: Envplastics

Several Benefits of Plastics

The first benefit of plastics is the ability to stay with living tissues without harming them. Since a cage in the hospital affects air, ability to stay without causing harm to the air is vital. Most types of plastic are able to do this.

Plastics are also good for cages because of their ability to clean easily. Research shows that plastics have good cleaning traits. This is a vital trait for medical device cages, which require regular cleaning. Most plastics are not affected by cleaning methods used in hospitals.

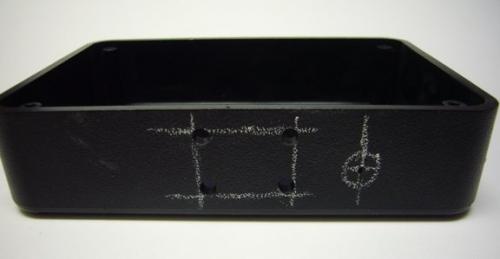

Plastic is also good for its ability to fight off damage from. The hospital staff exposes medical tools to many types of chemicals during the cleaning processes. Though all plastics are able to resist damage from chemicals, some are better than others are. If you will be cleaning the cage frequently, PC and ABS are the most suitable plastics to use.

Plastic is also popular for good mechanical qualities. Plastic mechanical qualities include resistance to fight off wear, hardness, and strength. Plastics that hospitals use have good mechanical traits. Such traits enable medical tool cages to perform well regardless of the coldness or hotness.

Plastic items in the hospital also have the ability to work well under heavy weight. Some medical tools operate in areas with heavy weights. Such places expose the cages to wear. One of the biggest benefits of plastic is that it has a lot of strength. Research shows that some plastics are four times stronger than fiber glass.

Have you seen how easy it is to cut plastic? This is because plastic has the ability to bend easily and does not break easily. This is vital because you may need to change medical devices often. Other items such as fiber glass and steel are not as easy to deal with since they are not as stiff as plastic.

Plastic is also cheaper than the other items used for cages. Steel is the most costly cage item. Fiber glass is more costly than plastic, although this is by a small margin.

Plastics with good look also come to mind when you consider the benefits of medical device plastic cage. As a user, I am sure you usually share medical devices. In addition, it is common for people to transport the items from one place to another. Therefore, you need to buy a plastic cage that is durable. A plastic cage in the hospital also needs to look good. This makes patients feel good.

Conclusion

You need to compare the working air with how suitable the selected plastic enclosure is. Nowadays, the goodness of plastics for the hospital has made work easier for those who plan and make the cages.

Some types of plastics are very popular because of their traits. Such items are suitable for cleaning, exposure to the sun, exposure to chemicals, among others.

Makers are trying to make hospital items that are good for the air in the hospital. These items should also be movable and good looking. This means that people are more careful when choosing the items they use for cages. Planners and users choose the available items depending on several factors. Examples of such factors are performance, look, and ability to last.

Taking the right item for medical device enclosure is a matter of looking at the hospital air. The air in the hospital exposes items to hotness, cold, chemicals, abrasiveness, and others.