Providing protection for your computers and other devices is an important part of your overall network. One easy way to do this is to encase your devices in custom plastic enclosures. These enclosures are made from a molded plastic based on plans or a prototype of your item that you need to protect. The rounded edges and soft color (if you so desire) will make it a complementary piece of your office, not just a necessity. The sturdy ABS plastic will also be long lasting.

Providing protection for your computers and other devices is an important part of your overall network. One easy way to do this is to encase your devices in custom plastic enclosures. These enclosures are made from a molded plastic based on plans or a prototype of your item that you need to protect. The rounded edges and soft color (if you so desire) will make it a complementary piece of your office, not just a necessity. The sturdy ABS plastic will also be long lasting.

Enclosures are reasonably priced, so your entire office can be taken care of. The lightness of the plastic means the enclosures can be used with portable devices, too. Should you have to move offices, enclosures can ensure that your computers will not be knocked about and damaged as a result. The plastic used in manufacturing can also come with UV protection, so your items will not face damage from the sun or overhead lighting.

Custom plastic enclosures should meet the requirements as outlined by the European Union in the Registration, Evaluation, Authorization and Restriction of Chemicals Directive, or REACH. This regulation was enacted to ensure that any chemical products entering the EU in excess of 100 tons are registered with the appropriate agency. This helps regulate chemical use so that the Earth stays cleaner. There is also the Restriction of Hazardous Substances Directive, or RoHS, that your product should comply with. This regulates the proper handling and use of six common yet hazardous chemicals used in electronics manufacturing.

Not only should your enclosure be made safely, but it should also provide you a level of protection against toxic fumes being emitted, which you otherwise would have to be breathing in.

A plastic enclosure can shield your device from electromagnetic or radio frequency interferences, too. These waves of energy can wreak serious havoc on electronics, causing gaps in information transfer or interfering with the paths of the circuits. When you are having your enclosure designed, be sure to include any ports you need cut into the plastic so that your cords and cables can be plugged in and not leave any areas unnecessarily exposed to energy waves, dust, or other environmental agents.

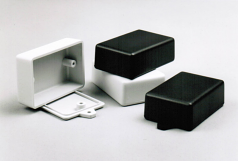

Some of the custom plastic enclosures you can have made include computer cases, portable device cases, DIN rail boxes, utility boxes, and potting boxes. Potting provides an exceptional level of shock protection for your circuit boards, and it shields boards from corrosion.

Your custom made enclosure can even have your company logo printed on the case or etched in, so that your new case can be even more functional than before.

When you buy directly from the company that produces the custom plastic enclosures you have two benefits. The first is being able to communicate with them exactly what you need so that you get just what you want. You have a person you can talk to who will make sure your order is just right. The second is the cost saving that comes from not having to talk to a designer and then have that person ship the design to an outside firm.

Manufacturing has proven to be quite a significant sector in the last century and it is still growing at fast pace. Nearly every sector requires undertaking production and development initiatives. As such, certain specialized companies manufacture specific products for making secondary products in turn. Once these products are created, they normally then require getting packaged for the final touch. For this purpose, custom plastic electronic enclosures are necessary.

Manufacturing has proven to be quite a significant sector in the last century and it is still growing at fast pace. Nearly every sector requires undertaking production and development initiatives. As such, certain specialized companies manufacture specific products for making secondary products in turn. Once these products are created, they normally then require getting packaged for the final touch. For this purpose, custom plastic electronic enclosures are necessary.

Providing protection for your computers and other devices is an important part of your overall network. One easy way to do this is to encase your devices in custom

Providing protection for your computers and other devices is an important part of your overall network. One easy way to do this is to encase your devices in custom